Pulp Egg Tray Making Machine Properties

A pulp egg tray making machine is a piece of industrial machinery that can turn waste paper-based materials into pulp molded products, like egg cartons, eggs trays, and apple trays. The cost and availability of raw materials to run such a paper egg tray making machine for sale are excellent, and the output rate of the best machines can exceed 9000 pieces per hour. Consequently, running an egg tray manufacturing businesses can be a very profitable venture.

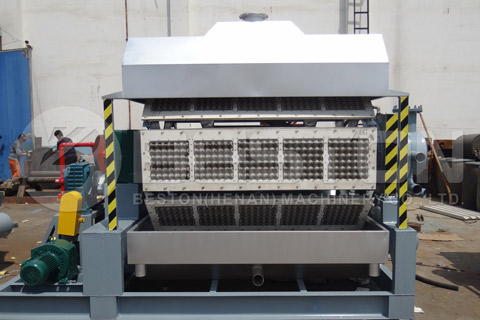

One manufacturer who has been in the egg tray making machine industry for over two decades is Beston Machinery. The manufacturer sells all different configurations of machines, but one of their most popular models is the four-sided paper moulding machine. That machine appeals to a broad customer base because it is medium-sized and relatively affordable.

Beston Machinery has spent years developing the very best engineering technology for pulp molded product manufacturing, and they are somewhat famous among the globe’s largest egg packaging manufacturing companies. They have customers from all over the globe including customers from India, South Africa, Indonesia, the Philippines, Germany, Norway, etc. They export all their machinery worldwide.

There are two different models of four-sided paper egg tray making machines available: the BFT-3 and the BFT-4. The BFT-3 has an output rate of 2000 pieces/hour, a mold quantity of 12, a total power rating of 53.7 KW, an hourly electricity consumption rate of 37.59 KW, a paper consumption rate of 170kg per hour and labor force operational requirement of 4 to 6 personnel. The BFT-4 has an output rate of 2500 pieces/hour, a mold quantity of 16, a total power rating of 57 KW, an hourly electricity consumption rate of 39.9 KW, a paper consumption rate of 212kg per hour and labor force operational requirement of 4 to 6 personnel.

Benefits Of High-Quality Pulp Egg Tray Making Machine

1. High stability. When the best engineering technology is employed, machine stability is enhanced. The best machines have very low failure rates and produce high-quality paper molded products. The use of automation means there are fewer places in the production line where human error can occur.

2. Uses cheap, sustainable raw materials. An egg tray making machine is a great piece of equipment for recycling old newspapers, old books, scrap paper, and discarded cartons. Waste paper is easy to obtain for very low prices from local waste processing facilities. Besides, this blog has some description about this machine: https://lindakimble.doodlekit.com/.

3. Low running costs. Energy-efficient machines have low running costs, so operators are able to make higher profits from the end products.

Drying Systems For Paper Egg Tray Machines

Keep in mind that you can use a range of drying systems with a pulp molding machine. The cheapest option is to utilize a natural drying system, but such a system can limit production rates. The other options are brick drying systems and metal drying systems. Each type of system has its advantages and drawbacks. You will need to analyze the direction of your business in order to determine which type of drying system will be the best investment. Start this business here: https://BestonTurkey.com/.