Scrap Tire Pyrolysis Plant Business Plans

Are you thinking about launching a tire recycling business this coming year in a bid to capitalize on the lucrative green industry? If so, you need to understand that there are lots of different eco-friendly waste tire to oil machines available and each one has different setup costs, features, advantages, and drawbacks. In other words, buyer research is essential when it comes to investing in a waste tyres pyrolysis plant.

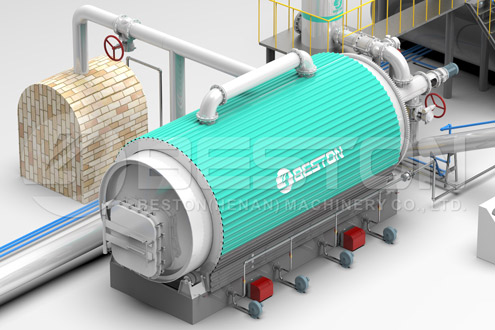

The latest tire pyrolysis plants, for instance, are fitted with advanced filtering systems and energy-efficient components, which means they are cheaper to operate and they have better green credentials. A lot of people are unaware of how much filters have advanced over the last five years. Modern tire to oil machines are built to match stricter emissions regulations, so they are generally a wiser investment than some of the earlier models, especially if your business is looking to access government subsidies for green credentials.

Just like with any other type of business, creating a detailed business plan is vital for all those looking to enter the lucrative tire recycling industry. The plan needs to be centered around the cost of the largest initial business expense, which is almost certain to be the small pyrolysis plant. That said, you also need to take all of the other associated factors and costs into consideration when drawing up a plan.

Those who hate writing business plans from scratch will be pleased to learn that there are many free waste tire pyrolysis plant business plan templates available online. These templates are easy to customize to your own operations, and can help you to outline and identify all the cost factors surrounding your vision. It’s important to keep in mind that a detailed tire recycling plant business plan will be essential if you are looking to obtain business loans, startup capital from private investors or green business grants from your state government.

Besides the cost of the machinery, some of the other costs linked to starting a modern scrap tire processing plant include the cost of obtaining a constant supply of raw materials, the cost of land, the cost of machine maintenance, workforce costs, insurance costs and much more. If you are planning to start a very large recycling operation, such as a facility that processes over 25 tons of waste rubber each day, it would be advisable to consult with experts who have experience in the tire recycling industry.