Review On Tyre To Oil Plant Process

Taking waste tyres and converting them to oil is an ideal method that can be used to remedy the problems that are caused by excess waste tyres. With the energy issues that are abundant in every country in the world, there is an ever greater need to try and use this type of waste product as an alternative source of energy.

What Are The Steps In The Waste Tyre To Oil Process?

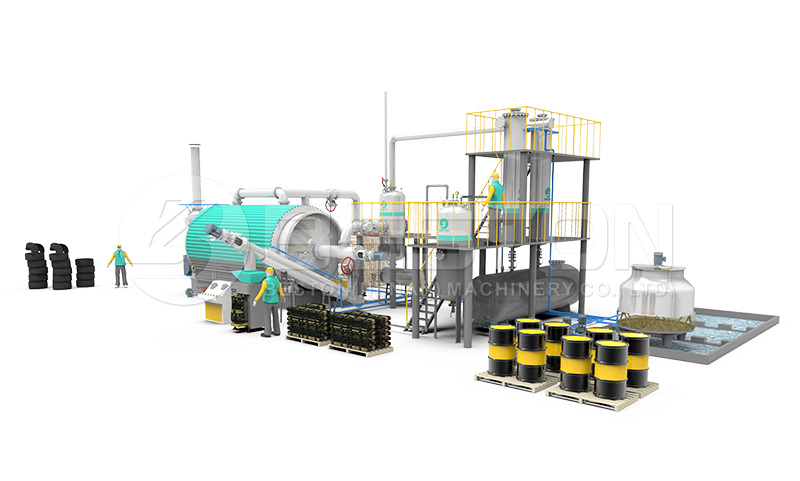

The waste tyre to oil process is also known as a pyrolysis process. This means that in order to convert waste tires into oil, the tires must decompose via high heat. However, before you begin to use the waste tire pyrolysis plant, there are several steps that you must complete first.

One of the first things that you will need to do is remove the steel wire out of the tires before processing them.

The next thing that you will need to do is ensure that the waste tyres size meets the standard for the processing plant you are using. For Example, for a continuous and semi-continuous waste tyre oil manufacturing plant, the size of the tyres should approximately 50mm. For a batch operating waste tyre oil manufacturing plant, the tire size should be under 1200mm.

Tire Recycling Process

After completing these steps, the actual operation to convert waste tyres to oil begins. The waste tyres must be placed into the reactor. Once the waste tyres are in the reactor, the reactor should be heated by using fuel sources such as wood, coal, fuel gas, etc. You can also check the link here for more details about mobile pyrolysis unit.

Once the temperature inside of the reactor reaches close to 120 degrees, the oil gas will be created. Some of the oil gas will then go into the reactor’s condensing system. It is there where the gas will be transformed into liquid oil. The gas that is left over, the gas that does not covert into liquid, will return to the combustion system after it has gone through the purification system. This gas can be used as a type of fuel material that can be used to increase the temperature of the reactor. As a result, the entire process will save energy. Once the oil production process has been completed, the reactor’s temperature will be cooled back down. When the reactor is cooled, carbon black will be instantly produced.

Dedusting is a process that can process smoke. This system makes sure that the smoke does not create any pollution in the air.

When the process is completed, you will end up with approximately: 45% oil fuel, 35% carbon black, 12% steel wire and 8% combustible gas.

These are all end products created by the waste tyre to oil process and they are not only beneficial energy sources, but they also have several other applications. More details about the pyrolysis process can be found from a skid-mounted pyrolysis plant.

Applications

The oil fuel can be utilized as a fuel material in the industrial sector. It can not only be used for burning, but it can also be used refined further to become diesel fuel.

Steel wire can be either recycled or resold in the steel industry in order to create new steel materials and products. See the scrap tire shredder here.

A tyre processing plant is safe and energy-efficient. They help to create new products that can be used in several industries through an environmentally friendly process.