How To Start Tire Recycling Business

Tire recycling business revolves around taking waste tires and converting them to products that can be used in various applications. The environmental benefits derived from recycling tires cannot be overstated enough. However, there for entrepreneurs, tire recycling with pyrolysis is important because it presents a growing business opportunity. If you are looking for pyrolysis plant for sale, you can check the tire to oil plant.

Tire recycling is an ever-growing industry. For instance, statistics show that in 1990, about 11% of used tires in the U.S. were recycled into raw materials that can be used in other applications as raw materials. However, the tire recycling industry’s growth has ensured that over 81.4% of the scrap tires have been recycled (https://www.ustires.org/scrap-tire-markets).

Recycling tires offer plenty of opportunities to generate new materials, including:

– Ground rubber is used in manufacturing rubber products such as mats, rubber modified asphalt, and much more.

– Tire-derived fuel is an excellent source of heat for industries such as cement manufacture and paper production.

– Ground rubber for civil engineering.

Starting a tire recycling business is not a complicated endeavor. With a 5 step approach to starting the business, you can get your tire recycling business up and running. More about the small pyrolysis plant cost.

#1. Find A Source And Market

When exploring the tyre recycling business, the first step is to find the source of tires and the market for the output. Naturally, the best sources for tires are the local opportunities. Find out what happens to the local tire waste. Additionally, consult automotive repair shops, tire retailers, taxi companies and bus operators, trucking companies, and any car company with a large fleet to know what they do with used tires.

On the other end, find customers for your products. Are there manufacturing plants that will benefit from tire-derived fuels? Talk to pulp and paper mills, institutions that run boilers, cement plants, and electric utilities companies to gauge their appetite for tire-derived fuels. Look for opportunities where you can sell ground and crumb rubber.

The gist of this phase is to understand a potential supply and demand chain for your products.

#2. Niche Down

While there are numerous uses for your products, you will increase your odds of succeeding by niching down. Select a niche you want to serve and dedicate all your efforts to be the best in that niche. Whether you want to serve industries by providing tire-derived fuels or supply ground and crumb tires, you need to select your niche.

#3. Find A Location

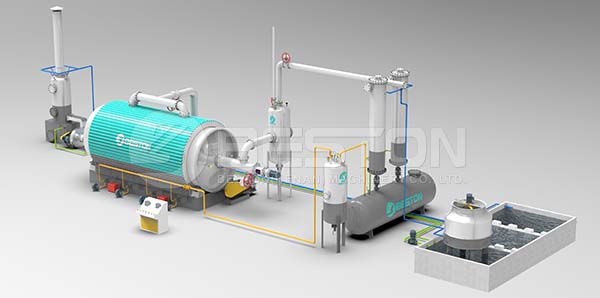

Conduct a site analysis and choose the best site centrally located between your source of scrap tires and the market for end products. Moreover, ensure you understand the zoning in force. Tire recycling is not only loud, but it is also messy and dusty, hence the need to be located away from many people. Additionally, the site must have ample space to accommodate many tires, the equipment and store the end products. Below is Beston tyre pyrolysis plant UK.

#4. Invest In The Right Equipment And Labor

The machinery and labor force needed for tire shredding and pyrolysis are different. As such, depending on the product you want to derive from scrapping tires, choose the right equipment, and select the right labor force (or train them).

#5. Acquire All The Necessary Paper-Work

Before you start operating, you must have the proper licenses and permits. If you need approval from your local, state, or federal agencies, get their approval. Ensure you have an intricate understanding of environmental regulation you must follow and operate strict adherence to the regulations. See the pyrolysis plant in the Philippines here.