How Does A Rice Hull Carbonizer Work?

A Rice Hull and Husk Carbonizer take the husks, hulls, and the coverings surrounding rice grains and convert these products into a form of charcoal. The hulls and husks on rice are usually removed and discarded. The process involved to turn hulls and husks into charcoal is one of the environmentally sustainable alternatives to provide an energy or heat source.

Here is an overview of how a Rice Husk Carbonizer works:

– What Is Carbonization?

The carbonization process involves converting organic matter such as animals and plants into char or carbon. This is a process that occurs in nature that results in ore, charcoal, and a few other minerals contained underground. However, these processes in nature are extremely slow and often take hundreds of years. Man has since invented numerous techniques and methods to speed these processes up. A rice hull carbonizer is one of these inventions that uses a high temperature and other required processes that turn the rice hulls into charcoal.

– The Working Process Of A Rice Husk Carbonizer

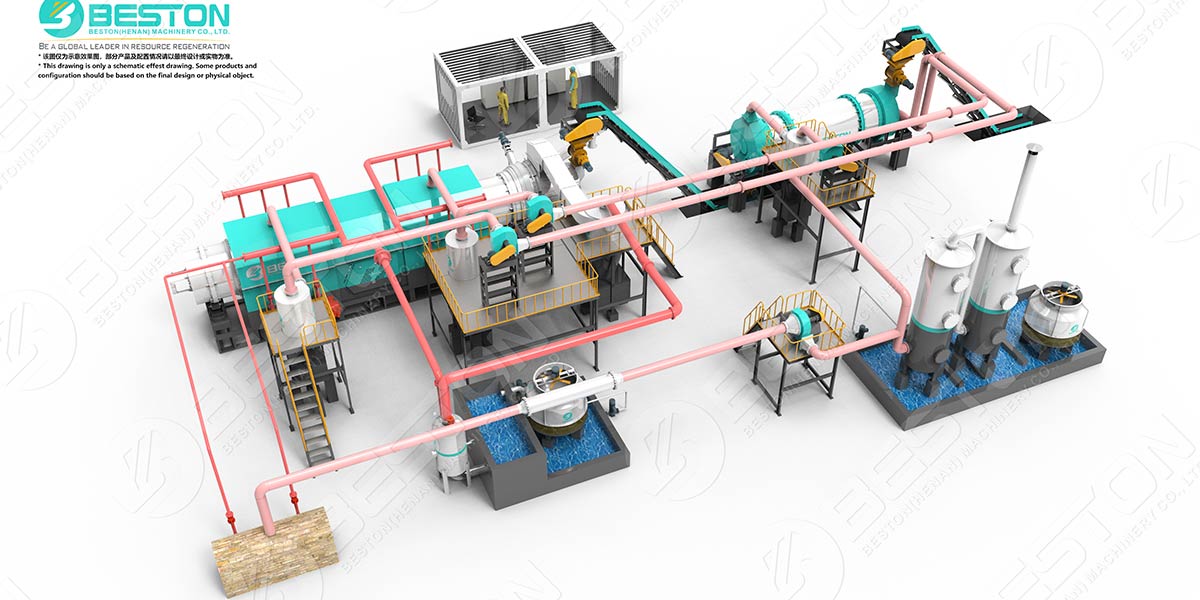

A Carbonizer Machine includes 4 major parts:

– Carbonization machine or chamber

– Gasification furnace

– Cooling chamber

– Flue gas purification system

The rice hulls first go into a carbonization furnace. The hulls and husks are then charred or burnt. These processes produce tar, flue gas, and a few other byproducts. See the wood to charcoal machine here.

The next step of the process involves a flue gas purification system. Gas that is created inside the furnace along with other impurities and tar is removed. This system is designed to filter the gas produced from the raw charred material which results in a purer end product.

The flue gas forms an important part of the overall carbonization process. The gas produced through the carbonization process is then sent into the carbonization chamber of the sawdust charcoal making machine where it is used for the combustion of the raw materials. This process of combustion provides the high temperature needed to convert the rice hulls into char or charcoal. The burning process releases more of the flue gas that is then continuously used to continue the process of combustion.

This continuous and closed cycle of combustion and the release of flue gas is described as circular and occurs in a “closed” environment. Since the environment is closed and sealed the process is smoke-free when converting rice husks and hulls into char or charcoal. Since the system is closed and the emissions of gas are utilized as a portion of the carbonization process, this alternative is environmentally friendly when compared to other processes.

The charcoal or char rice hulls then get sent into a cooling chamber. The charcoal needs to be cooled quickly to achieve a favorable end product.

The Rice Hull Carbonization machine produces a non-toxic and clean activated charcoal. The end products are also a quality energy source which means it is also in high demand. This is one of the main reasons that these machines have increased in popularity to match up to the demands for activated and clean charcoal products. Get high quality bamboo charcoal making machine here.